The Cutting Data For MUH-IGM4000 Series

| Material |

Alloy steel、Carbon steel |

| Shank(mm) |

n(min) |

Vf(mm/min) |

| Side |

Slotted |

| 4 |

6000 |

1100 |

420 |

| 6 |

4000 |

800 |

420 |

| 8 |

2900 |

950 |

420 |

| 10 |

2400 |

750 |

420 |

| 12 |

1900 |

500 |

420 |

| 16 |

1500 |

480 |

420 |

| 20 |

1200 |

400 |

420 |

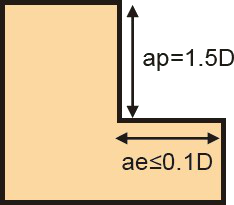

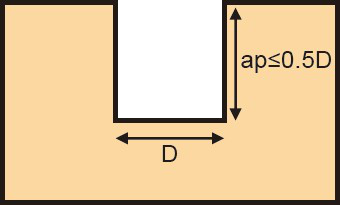

Depth

(D:F.D) |

|

|

Introducing the Carbide End Mill by Echaintool, meticulously crafted to meet the demands of precision machining. With features like Rounded Land Irregular Pitch and a helix angle options of 42°/45°, this end mill ensures smoother cutting and reduced vibration, enhancing machining accuracy and surface finish.

The Grade G300 shank provides durability and stability during machining operations, while the square end mill design offers versatility for various cutting tasks. The flute length, set at 2.5 times the diameter of cutting, facilitates efficient chip removal and stable cutting performance.

Available in diameters ranging from 4mm to 12mm, with corresponding full lengths and shank sizes, this end mill caters to diverse machining requirements. Equipped with four flutes, an unequal spiral, and unequal division, it delivers precise and consistent results across different materials.

Crafted from high-quality Micro Grain Carbide with an Altin coating, this end mill offers exceptional wear resistance and heat dissipation, ensuring prolonged tool life and enhanced productivity. With a cobalt content of 12%, it possesses the toughness required for machining various workpieces with a hardness of up to HRC<60.

Manufactured in Taiwan, the Carbide End Mill by Echaintool undergoes rigorous processing techniques such as angular plunge grinding, chamfer slotted, and full slot machining to guarantee superior quality and performance. Trust in Echaintool for precision, reliability, and efficiency in your machining operations.

MUH-IGM 4000

Round land Unequal Spiral Unequal Division 4 Flutes Carbide End Mill